botspot's Digital Spray Technology

Photogrammetry, the 3D scanning method of using a collection of 2D images to create a 3D model, is a widely used method for creating detailed models, providing a non-invasive system of obtaining high-quality texture and geometric data. However, certain surfaces pose significant challenges. Plain black surfaces, monochrome materials, and smooth, textureless objects often lead to inaccurate models, with errors such as bumps, holes, or distortions. These issues arise because photogrammetry software relies on unique visual features to align and reconstruct images into a 3D structure. When an object lacks distinguishable features, the software struggles to match images correctly.

At botspot, we have developed a technique to address this issue: our “Digital Spray”, which is essentially pattern projection using random noise. By projecting a dispersed noise pattern onto the object during scanning, additional reference points are introduced, significantly improving the accuracy of photogrammetric reconstructions.

How Pattern Projection Improves 3D Scans

This method involves taking two sets of images. The first set is captured with the pattern projection, where the introduced artificial surface texture helps the photogrammetry software align images and build an accurate geometric mesh. The second set is taken without the pattern projection, allowing the true surface texture of the object to be recorded. By combining these two sets, the result is a highly accurate 3D model with both precise geometry and realistic texture. This technique is particularly useful for objects that are traditionally difficult to scan, such as plain black clothing, monochrome surfaces, and human skin tones with low contrast.

Optimal Conditions for Pattern Projection

For the best results, certain conditions enhance the effectiveness of this technique. Controlled lighting is crucial, as a darker environment allows the projected pattern to appear more clearly and increases its effectiveness. The projector lens must also be properly focused, similar to a camera lens, to ensure that the pattern is sharp on the object. The projection itself does not need to be dynamic; a single static noise pattern is sufficient for the software to extract useful reference points. When all these factors are optimized, the technique can drastically improve the quality of photogrammetric scans, making previously difficult surfaces far more scannable.

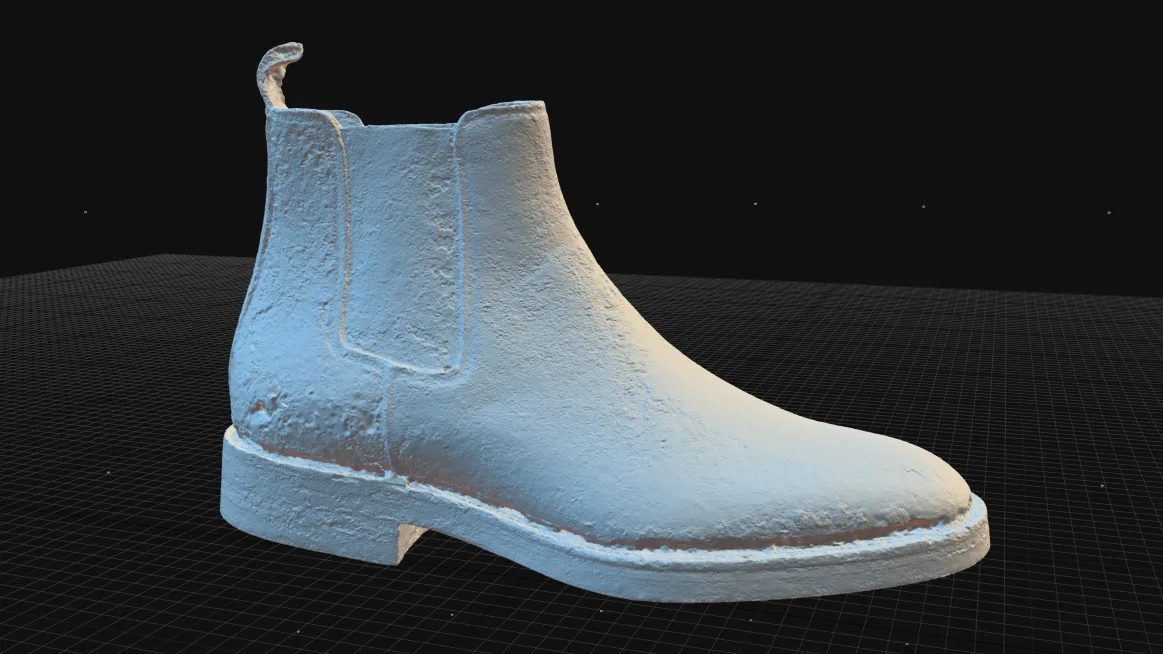

Case Study: Black Leather Boot

To showcase the results of this technology, here is a side-by-side comparison of a black leather boot 3D scan with and without pattern. Scanning a black leather boot presents unique challenges due to its combination of a dark, monochrome surface and varying levels of shininess. Traditional photogrammetry struggles to capture the boot’s geometry accurately because its uniform black color provides few natural reference points for the software, leading to errors such as bumps, distortions, and incomplete mesh generation.

Above is the 3D model geometry without botspot's Digital Spray, and below, with.

Simplicity and Safety

Our Digital Spray technology provides an efficient and non-invasive alternative to other 3D scanning methods. This method captures geometrically accurate models in the time it takes to take a photograph, whereas LiDAR scanning can take significantly longer to process. There is no need for scanning spray, allowing for detailed scans without physically modifying the object. The simplicity of implementation is another advantage, as it only requires a standard projector and controlled lighting without the need for additional calibration beyond standard photogrammetry workflows.

Applications in Various Industries

Beyond improving scans of clothing and monochrome objects, this method has applications across multiple industries. The fashion and apparel industry benefits from highly accurate 3D representations of garments, regardless of their color or fabric. In medical imaging, the technique enhances the accuracy of scans for people with darker skin tones, ensuring precise models for medical and cosmetic applications. Digital human creation for gaming and virtual reality also sees improvements in character scans, helping to create more lifelike digital representations. Additionally, forensic and historical documentation efforts can use this method to capture accurate digital records of objects and human figures without requiring any physical alterations to the subject being scanned.

Conclusion

Pattern projection is a valuable enhancement for photogrammetry, enabling accurate scans of surfaces that were previously difficult to capture. By introducing visual noise, this method improves the accuracy of geometric reconstruction while preserving true surface textures. Its applications span industries, from fashion and gaming to medical imaging and forensic documentation. As photogrammetry continues to evolve, innovations like this offer new possibilities for capturing high-fidelity 3D models with minimal equipment and setup.