3D Scanning Historical Costumes from the Filmmuseum Potsdam

In collaboration with Filmuniversität Babelsberg KONRAD WOLF and the Filmmuseum Potsdam, we recently had the opportunity to bring pieces of film history into the digital world. As part of a joint project, we scanned three historical costumes from the Filmmuseum’s collection, including the well-known costume from the 1973 opera film Ritter Blaubart — a DEFA studio production of Walter Felsenstein’s staging of Jacques Offenbach’s operetta Blaubart at the Komische Oper Berlin.

The collaboration aimed to explore how modern photogrammetry can be used to preserve and digitally reconstruct garments of cultural significance. Our company provided the scanning services and technology, while the Filmuniversität team investigated different methods of processing and using the resulting data.

The Scan Day

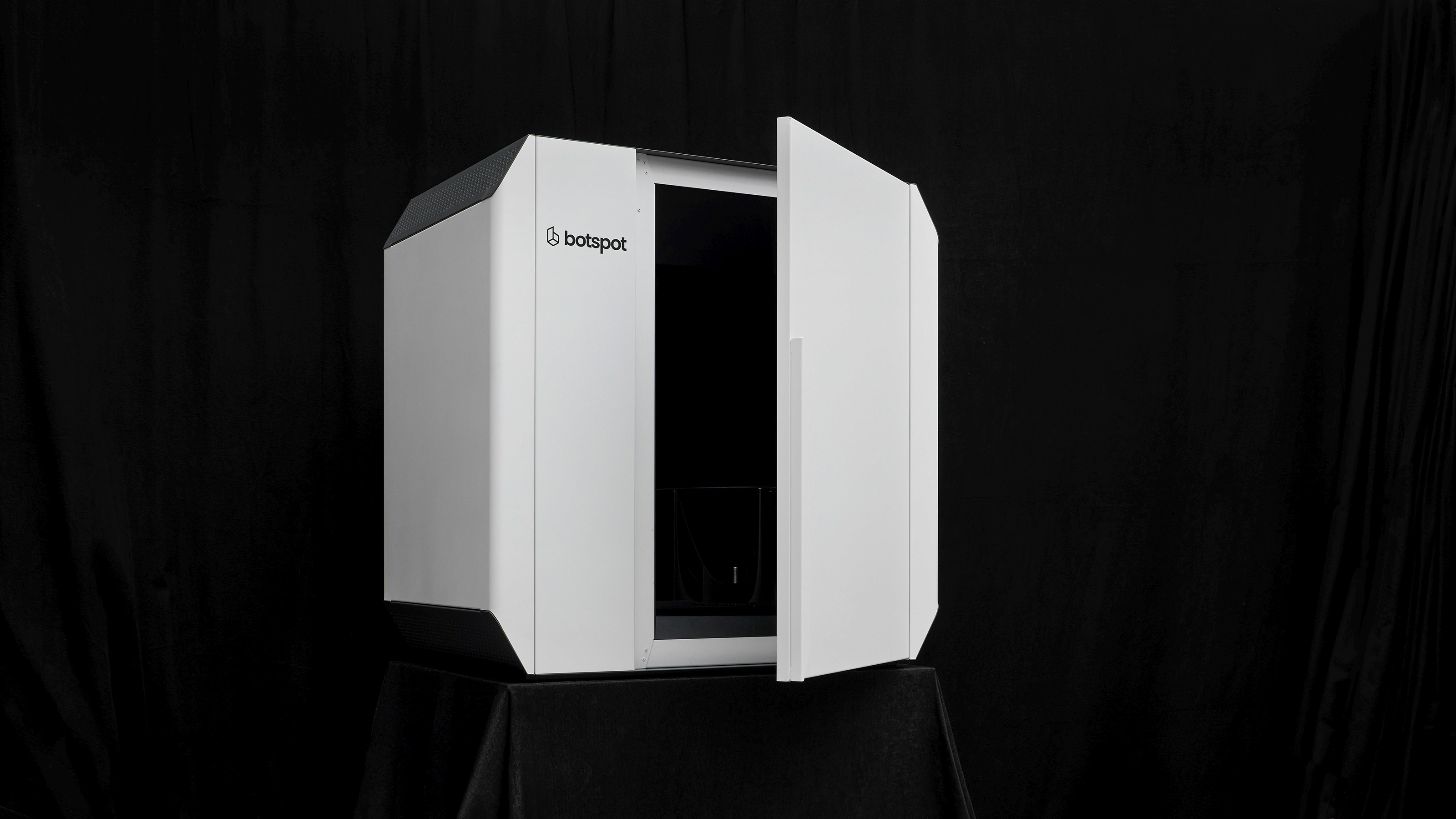

The scanning took place in our office, where representatives from all involved institutions joined us for a dedicated scan day. The historical costumes arrived on their original mannequins, handled by a museum specialist. Once carefully placed inside our full-body scanner NEO, each costume was digitized in detail from 160 angles.

Alongside the 3D scans, our photographer captured high-resolution close-ups of the fabrics. These detailed images revealed the texture of the materials, the precision of the stitching and the fine decorative elements that define each piece. To support the later digital reconstruction process, we also filmed the fabrics as they moved. These videos provided valuable insight into how the garments behave dynamically, helping the 3D artists to replicate the natural movement and drape of the fabric.

From Scan to 3D Model

After scanning, we delivered the raw 3D data to the team at Filmuniversität. Their traditional 3D artists began working with the unprocessed OBJ files generated directly from the scanner. The workflow followed a classic production pipeline: mesh optimization through retopology, UV unwrapping, and texturing.

Two texturing methods were tested. The first used the original photogrammetric texture from the scan, generated with RealityScan. The second employed the UDIM approach, which divides the texture into multiple high-resolution tiles. Both methods offer clear advantages. The scan texture provides a direct visual representation of the original material and is faster to implement, while UDIM texturing allows for higher fidelity and consistency across different render engines and production environments.

The traditional workflow has the strength of being versatile and reliable. It produces models that can be used for various purposes, from visual effects and animation to interactive media and virtual exhibitions. It also ensures physically accurate material behaviour once the model is animated. However, it remains a time-intensive process that requires significant manual work and expertise.

Exploring AI-Based Reconstruction

In parallel, the university’s AI department tested an experimental approach. Instead of relying on the manual 3D workflow, they used our scan data to feed AI systems trained for digital reconstruction and animation. The results were both surprising and promising. Some outputs showed people walking or dancing in the digitized costumes with impressive realism, while others produced more unusual and abstract interpretations.

Although still a work in progress, these experiments demonstrated how artificial intelligence could one day complement or even accelerate the traditional 3D production pipeline, offering new possibilities for digital heritage and creative industries alike.

Looking Ahead

This project is still ongoing. The models continue to be refined, and both the traditional and AI-based methods will evolve as the collaboration progresses. Beyond its immediate research value, this project highlights the broader potential of 3D scanning in the preservation and creative reuse of historical garments.

Digitizing costumes enables museums and film archives to preserve delicate textiles in digital form while allowing researchers, designers, and the public to explore them interactively. The same technology can also serve the fashion and retail industries — for instance, by enabling 3D configurators for online stores or by helping designers reverse engineer sewing patterns without physically handling the original garments.

We look forward to sharing future developments from this collaboration and are excited about the many directions in which this work could evolve.

We would like to thank everyone involved at Filmuniversität Babelsberg KONRAD WOLF and the Filmmuseum Potsdam for their trust, collaboration and expertise in making this project possible.

Share on Facebook

Share on X

Share on LinkedIn

Top 3 Photogrammetry Software in Review

Making the Momentum 2.0

3D Scanning Historical Costumes from the Filmmuseum Potsdam

How Body Measurement Technologies Are Advancing

How 3D Scanning is Advancing Prosthetic Design