Making the Momentum 2.0

At botspot, every product update begins with a simple question: how can we make 3D scanning more accurate, more reliable and more efficient for real workflows? The Momentum object scanner has served professionals in research, cultural heritage, product development and digital content creation for years. As these industries evolved, so did their expectations for precision, lighting control, automation and ease of use.

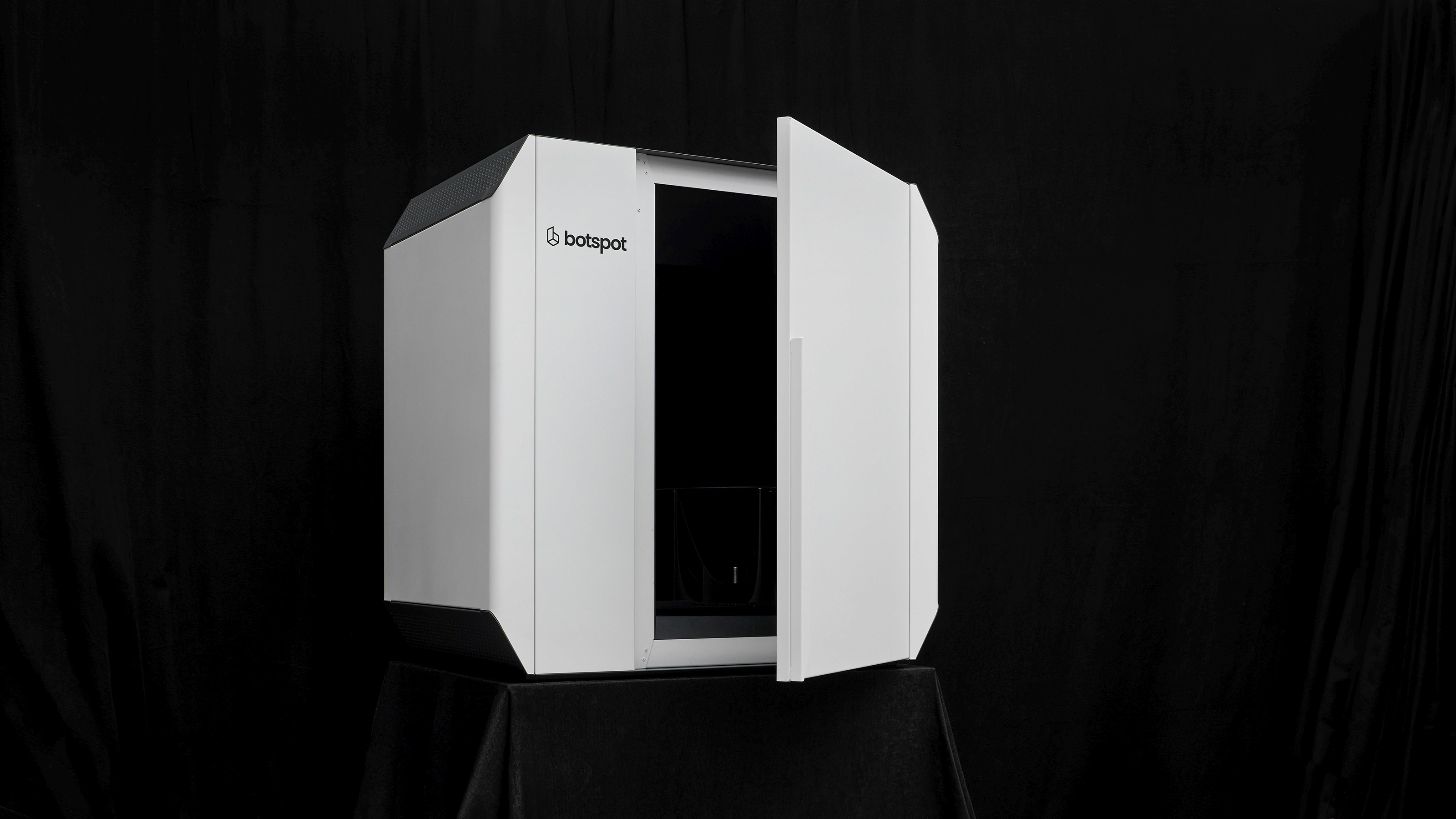

The Momentum 2.0 is the result of a comprehensive technical redesign based on those needs. It introduces improvements in optical control, lighting, mechanics and backend architecture while retaining the scanner’s compact, studio-ready form factor. The goal was not to rebuild the system from scratch, but to elevate every element that influences scan quality and operator experience.

Improved Optical Environment for Sharper Geometry

One of the most visible upgrades is the redesigned interior. The original white inlay has been replaced with a matte black environment that significantly reduces stray reflections. This change allows the cameras to focus more precisely on the object’s surface, resulting in cleaner geometry, better-defined edges and more stable photogrammetric reconstruction, particularly with bright or glossy objects.

The new interior forms the foundation for the Momentum 2.0’s optical accuracy and complements the scanner’s updated illumination system.

Advanced Lighting for Greater Surface Detail

Lighting plays a crucial role in small-object scanning, and the Momentum 2.0 introduces several improvements that offer more control and more consistent results.

LED lighting has been added beneath the turntable to illuminate the object from below. This bottom-up lighting reduces deep shadows around bases, overhangs or recessed features, enabling more complete surface capture.

To support objects of different sizes and to maintain image quality at various camera zoom levels, the scanner now incorporates retractable light covers. These covers can be positioned to shield the LEDs when scanning larger items, preventing the lights from appearing in the background of captured images. When additional illumination is required, the covers can be retracted to allow more light to reach the object. This mechanical flexibility offers precise control without complicating the workflow.

More Accurate Object Placement through Mechanical Refinements

Accurate scanning begins with correct object placement, and several upgrades were developed to make this step more precise and intuitive.

The Momentum 2.0 now includes a set of interchangeable glass turntable holders at different heights. This allows users to position objects optimally depending on their size, desired field of view or lighting requirements. Elevation flexibility improves both geometry quality and texture uniformity.

To ensure consistent centering, the scanner is equipped with an integrated laser pointer aligned to the center of the turntable. Operators can see immediately whether an object is correctly positioned, reducing alignment errors and improving reconstruction accuracy. This feature is particularly valuable for small or symmetrical objects where visual estimation is difficult.

Updated Backend Architecture for Stable, High-Performance Processing

Behind the hardware and optical improvements lies one of the most significant changes to the Momentum platform: a completely modernized backend designed for stability, speed and long-term maintainability.

The Momentum 2.0 now runs on an updated Linux-based control system built around the Opta Finder (PLC). Core tasks such as camera triggering, turntable control, synchronization and sensor logic operate on a dedicated microcomputer isolated from the reconstruction workstation. This ensures real-time responsiveness during capture and prevents interruptions even during heavy processing loads.

A new integrated router and switch architecture provides a stable networking backbone inside the device. Cameras, sensors and control units communicate over a dedicated internal network, independent of external studio setups. This upgrade eliminates connectivity bottlenecks and simplifies deployment in labs, museums or multi-user environments.

For processing the captured data, the system is powered by high-speed CPUs and CUDA-enabled GPUs, allowing RealityCapture workflows—and custom botspot scan-to-3D automation—to run efficiently and predictably. Users can choose resolutions, polygon targets and texture output that match their production needs, whether the final model is destined for scientific analysis or lightweight real-time 3D.

Together, these backend improvements create a more resilient, faster and more user-friendly scanning experience, even for complex objects or high-throughput workflows.

Streamlined Scan-to-3D Workflows

As part of the redesign, we reworked the Momentum’s automation layer to make the entire process—from capture to textured 3D model—more intuitive and more adaptable.

The updated botspot Automation Suite brings camera control, lighting management, turntable synchronization and reconstruction presets into a single, browser-based interface. Operators can launch scans, adjust settings, review captures and monitor progress without needing photogrammetry expertise.

For advanced users, custom modes allow fine-tuned control over exposure, resolution, polygon density and post-processing. For new users, the standard presets ensure consistent, high-quality results with minimal setup.

This balance between automation and flexibility is a defining characteristic of the Momentum 2.0: the system adapts to the workflow, not the other way around.

A More Capable Scanner in the Same Compact Form Factor

While the underlying architecture and mechanical components have evolved, the Momentum 2.0 maintains one of its most important characteristics: its compact footprint.

Fitting naturally into desks, labs and studio workstations, it remains a self-contained scanning unit that does not require external lighting setups or complex calibration procedures. The redesign enhances its capabilities without increasing its size or operational complexity.

Professionals in research, product design, cultural heritage and digital content creation can continue using the scanner as a dependable part of their daily workflow—now with greater control, accuracy and consistency.

The New Standard for Small-Object Photogrammetry

The Momentum 2.0 brings a series of practical, engineering-driven improvements to a scanner that many professionals already rely on. By refining the optical environment, expanding lighting control, improving mechanical precision and updating the backend architecture, the new version delivers more consistent results across a wider range of object types.

These changes were introduced without altering the scanner’s compact form or its straightforward operation. Existing workflows remain familiar, but benefit from higher accuracy, more stable processing and more flexible configuration options.

The Momentum 2.0 is designed to support the everyday demands of research, digitization, product development and digital content creation, providing a reliable, modernized platform for small-object photogrammetry.